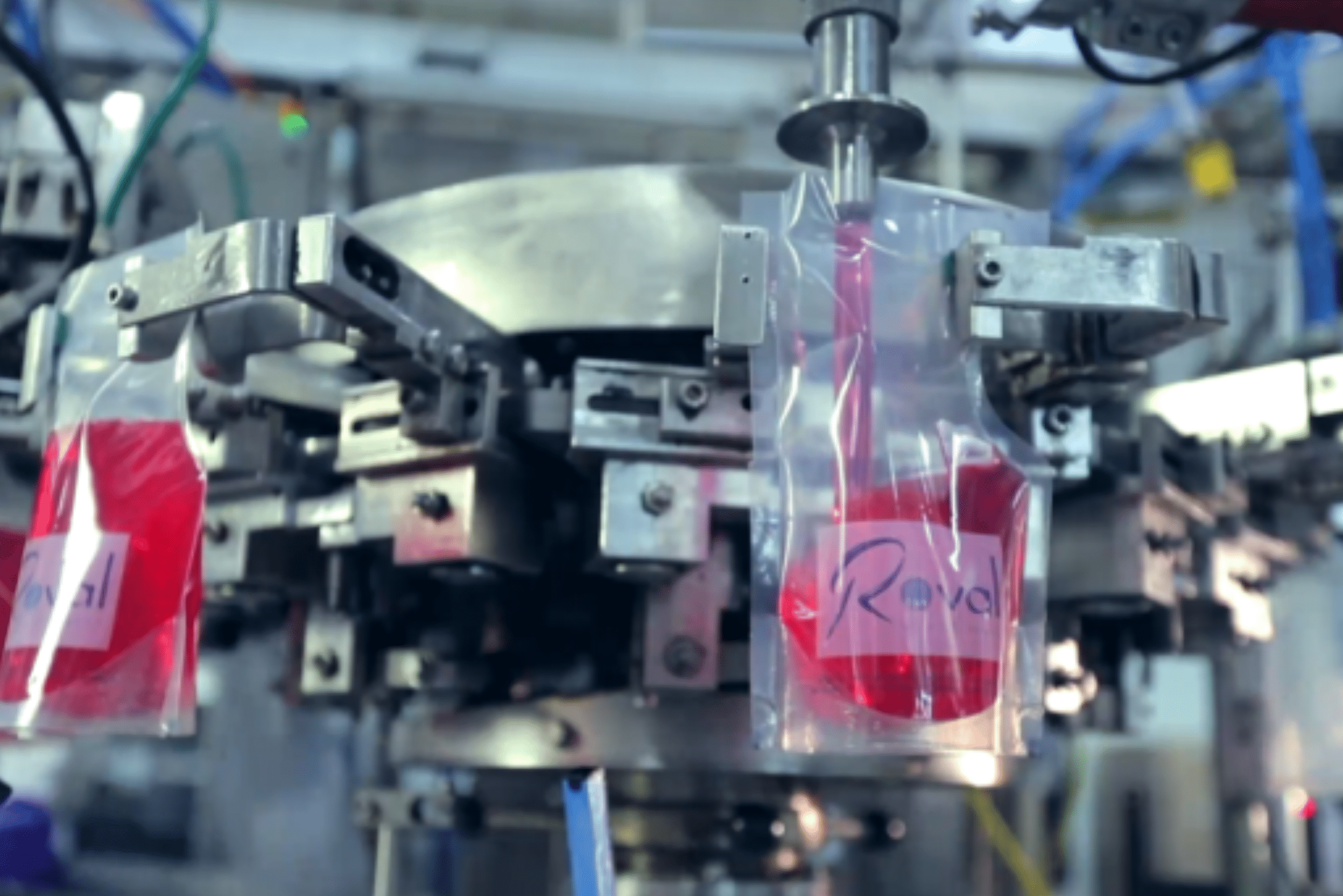

ROVAL Cosmetics

Expert in organic, natural and conventional hygiene and care products, ROVAL Cosmétique has been supporting the leaders of the cosmetics market for more than 43 years. The company offers full-service and tailor-made support to provide their customers with reduced time-to-market and rapid launches, in particular thanks to the in-house manufacturing of packaging (extrusion blow molding).

+550

collaborators

120

millions of revenue

185

millions of units produced per year

A digitalization of the entire industrial process

The project quickly took shape, driven by the discontinuation of maintenance for the existing WMS. This discontinuation also provided ROVAL Cosmétique with an opportunity to reassess their needs. Since the old WMS only covered the "finished products" section, the company wanted to computerize its logistics across its entire industrial process. The goal? To achieve real-time traceability and digitize batch records .

Our response

A vertical process

As part of this project, SITACI deployed a so-called "vertical" process. This translates in particular into the complete management of control activities :

- pre-weighing,

- Tolerance management,

- Sampling,

- Integration with existing weighing solutions or WCS

The main stages of the project

Deploying the EGO WMS in 5 steps

Initially, the project focused on raw material management, then expanded to include the manufacture of semi-finished products.

The sequence continued with the management of overflow sites and the automation of shuttles to supply production sites.

Finally, the project was pushed to packaging activities, and then ended with finished products.