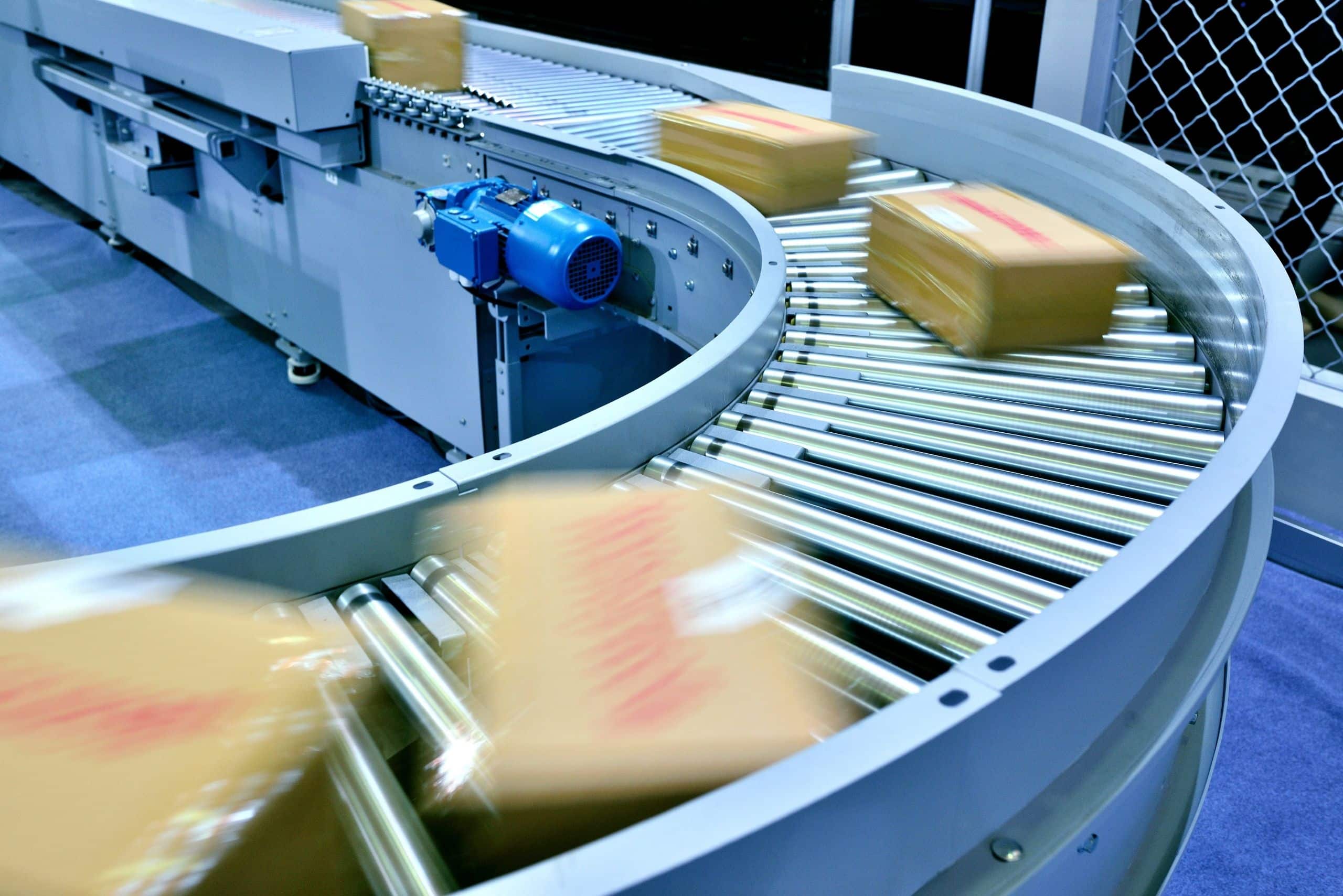

Discover our industrial logistics customers

100% BtoB and delivering to internal customers, industrial logistics is opposed to distribution logistics. Indeed, it concerns all activities and processes aimed at managing and optimizing the flow of goods supplying production lines, Business Units, or processing machines within a factory. The challenges to be met for this particular logistics are multiple and complex in order to meet very demanding internal demand.

Industrial logistics: specific needs

Effective management of production flows

Production flow management involves controlling and optimizing the movement of raw and/or components. All this requires:

- Plan supplies : ensure a continuous and balanced supply of raw materials to avoid interruptions.

- Coordinate operations : synchronize the different stages of production to ensure that each line operates smoothly and without downtime.

- Minimize travel time : Reduce travel between workstations to improve efficiency.

Optimization of storage space

The challenge? Organize storage areas strategically to facilitate rapid access to necessary and high-turnover materials, while optimizing available space.

Reduction of internal costs

Reducing internal costs requires optimizing processes and rigorous management of resources. To do this, companies must:

- Reduce excess inventory : Use inventory management techniques, such as just-in-time, to maintain minimum inventory levels without compromising production.

- Improve processes : identify and eliminate inefficiencies and waste in production processes using methods such as Lean Manufacturing.

Improved productivity

Improving productivity is a central subject in industrial logistics. It involves analyzing and reorganizing flows to avoid any bottlenecks and increase the speed of operations.

Don't forget: the implementation of performance monitoring via KPI's to monitor the efficiency of operations and identify areas requiring improvement.

Industrial logistics: what are the challenges?

Industrial logistics can be very complex and remains a pillar of business performance that should not be overlooked. In order to remain competitive in terms of productivity and efficiency, it must respond to the challenges of its supply chain.

Inventory and raw materials management

To avoid shortages and excess stocks , effective management of these as well as raw materials is mandatory. For this, it is necessary to:

- Rigorously plan requirements : Use demand forecasts and historical analyzes to plan raw material and component requirements.

- Track in real time : monitor stock levels and material movements. This makes it possible to react quickly to changes and adjust stock levels accordingly.

Traceability and product controls

The internal quality department is demanding. Traceability and control of products must be ensured to guarantee compliance with standards . To this end, the use of traceability systems, such as RFID or a WMS, to track products throughout the process is necessary. To this traceability is naturally added the implementation of quality controls at each stage of the process to detect and correct problems quickly.

Adaptation to production fluctuations

Industrial logistics must be flexible in order to adapt to variations in demand (seasonality or launch of new products for example) and to production hazards. This requires:

- Rapid response capability : Establish systems and processes to respond quickly to changes in demand and production interruptions.

- Forecast management : use forecasting tools to anticipate fluctuations in demand and adjust production plans accordingly.

The role of WMS in industrial logistics

The Warehouse Management System (WMS) provides real-time visibility of raw material and product movements, facilitating traceability and inventory management. It also optimizes storage space and process reducing errors by up to 99% and operational costs.

Why use EGO WMS?

Developed by logisticians for logisticians, our inventory management solution, the EGO WMS , benefits from more than 35 years of developments and adaptations. Fully configurable, EGO supports you in:

- Preparing lists to serve,

- The production declaration,

- Stock reintegration,

- Line edge management,

- Manufacturing orders (provision of the exact number of components for manufacturing),

- The production output,

- Management of ranges and nomenclatures.

The EGO solution tracks all logistics operations, from the preparation of components or raw materials, to the reintegration of stocks. Finally, the EGO WMS offers modules that comply with current regulations.

B2C

No posts found for this term.

Book a free demo

Contact us to book your EGO WMS demo

Ready to find out how we convinced more than 580 customers to optimize their logistics with EGO WMS?

Please fill out these fields

to book a demo