Warehouse 4.0 solutions

Logistics

4.0 solutions

Supply Chain

October 9, 2024

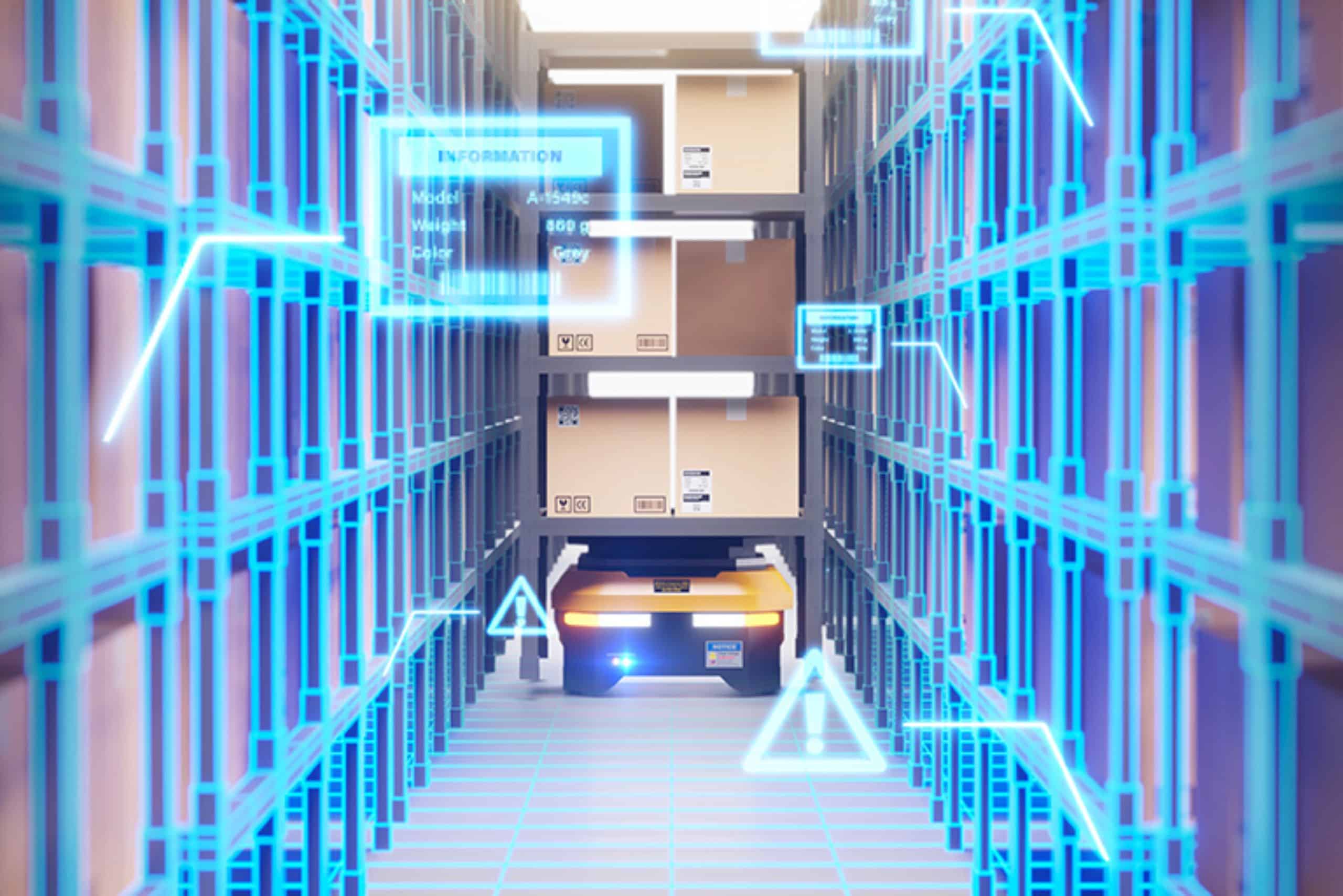

The term "Warehouse 4.0" encompasses all connected innovations and technologies whose practical applications enhance the performance of the supply chain, the personnel who work there, and therefore the company that implements them. Following the Factory of the Future, the logistics sector is now undergoing its own revolution thanks to the emergence of new technologies in the fields of infrastructure and IT.

So, what innovations and solutions are there to meet these logistical challenges? And how can these technologies help accelerate the transformation of businesses, both in their core operations and in their markets?

What are the challenges for warehouse logistics?

The challenges and issues faced by logistics managers mainly concern:

- Productivity,

- Error reduction,

- Synchronization,

- The service rate,

- Stock management

- Managing logistics activities.

To meet these challenges, all warehouse processes are involved. Indeed, this includes unloading, storage, replenishment, order picking, loading, support functions, and more

Today, new, mature and available infrastructure or IT solutions can address the majority of these challenges.

How can new technologies impact logistics?

Increase productivity

Thanks to new technologies, inventory productivity can be increased by automating counting using RFID scanning. It is also entirely feasible to boost receiving productivity by simplifying access to management and printing solutions, and/or to increase order picking productivity by reducing manual handling through direct cobot deployment to the packing area. All of this can be done while the order picker continues their picking activities. Productivity can also be improved by simplifying the identification of the correct package for shipping goods.

Among the solutions that can be connected to a WMS, we can mention the Husky intelligent cobot developed by the Nantes-based company E-Cobot , which can transform into a true assistant for operators:

- Picking/kitting,

- Post office supply

- Disposal of finished products,

- Small logistics train / milk run,

- Kanban management,

- Position-to-position transfer,

- Transfer to stock/shipping,

- Returns of empty bins,

- Waste disposal,

- Transporting tools

Improving the quality of stocks

Technological solutions can also improve inventory management by guiding operators to the correct storage location. Service quality can also be enhanced by reducing errors during order picking and loading.

Among the solutions that can be connected to a WMS, we can mention the dynamic storage system marketed by the company PTLS (Pick To Light System) indicating where to store goods in stock.

Synchronize information

Certain technologies can also provide enhanced information . For example, this information can relate to the location of picking carts to enable "guided driving" for operators in their daily tasks. It can also provide them with visual information about routes within the warehouse (wrapping, packaging, inspection).

They also allow for the optimization of storage strategies, enabling each operator to be assigned to a specific area and minimizing their movements, while providing dynamic information on key performance indicators (KPIs). These indicators then unite teams around common objectives (number of orders prepared, deliveries received, pallets awaiting storage, etc.). These technologies also help reduce administrative tasks such as scheduling carrier appointments or gathering evidence in the event of customer or carrier disputes.

In Virtus is developing a geolocation system for warehouse assets using IoT technology. TKH specializing in providing video evidence in warehouses, and Shiptify, which has developed a veritable "Doctolib" for scheduling carrier appointments, are also examples.

Optimize storage and transportation

Certain technologies allow for the analysis of how goods are stored , enabling the assignment of a better storage strategy to each item based on its properties. The goal is to reduce order preparation movements or limit the saturation of picking areas. This will allow for the reorganization of these areas or the replenishment of stock.

With the aim of optimizing stock levels, some solutions even go so far as to analyze and optimize the replenishment thresholds of a picking stock, thereby improving the use of space and the number of replenishments.

Finally, we could discuss solutions that increase inventory frequency without increasing the workload for staff. This improves the quality of inventory management. Algorithms smooth out receiving activity throughout the week without impacting resources or reducing the workload of the picking team, while technologies reduce the number of loading errors. All of this is possible by implementing checkpoints to ensure the correct aisle is used to load the correct semi-trailer. For example, French companies specializing in Artificial Intelligence, such as Fieldbox.io, have developed algorithms that enable dynamic slot allocation.

Most read articles

WMS software

Logistics

4.0 solutions

Supply Chain

December 5, 2025

AI and logistics: How is generative AI revolutionizing today's and tomorrow's supply chain?

Logistics, a true pillar of the global economy, is currently undergoing an unprecedented revolution. Indeed, traditional management methods are reaching their limits. How, in this context, can we move from reactive logistics to a proactive, agile, and resilient supply chain? The answer lies in two letters: AI, and more specifically, generative AI.

WMS software

Logistics

4.0 solutions

Supply Chain

December 12, 2025

Digital twin and 3D modeling: How these technologies are revolutionizing your warehouse

Imagine being able to test a major change to your logistics platform before even moving a single pallet. That's precisely the promise of 3D modeling and, above all, the digital twin of the warehouse.

WMS software

Logistics

Supply Chain

July 3, 2024

Inventory management using WMS software

To master your inventory management, it is imperative to use suitable and efficient inventory management software. With this automation, you can monitor the status of your inventory in real time, allowing you to make informed and rapid decisions to avoid stock-outs or overstocks.