Discuss your needs with our experts!

WMS EGO

Managing your warehouse has never been so simple: EGO a WMS that suits you.

For over 37 years

We support you

SITACI designs and publishes software and IT solutions applied to logistics. A pioneer in its sector, our company develops, implements and maintains its own WMS solution: EGO, Supply Chain Management.

How does WMS EGO work?

WMS

EGO

How do I develop my ego?

A robust standard base to which more than 25 additional modules to extend coverage and connect to its environment for an "augmented" WMS.

The EGO suite is designed to be dynamic and constantly evolving:

- 2 annual updates

- 70 to 100 new features added to the base

- are added each year and can be activated.

Why trust us? Here are 5 reasons.

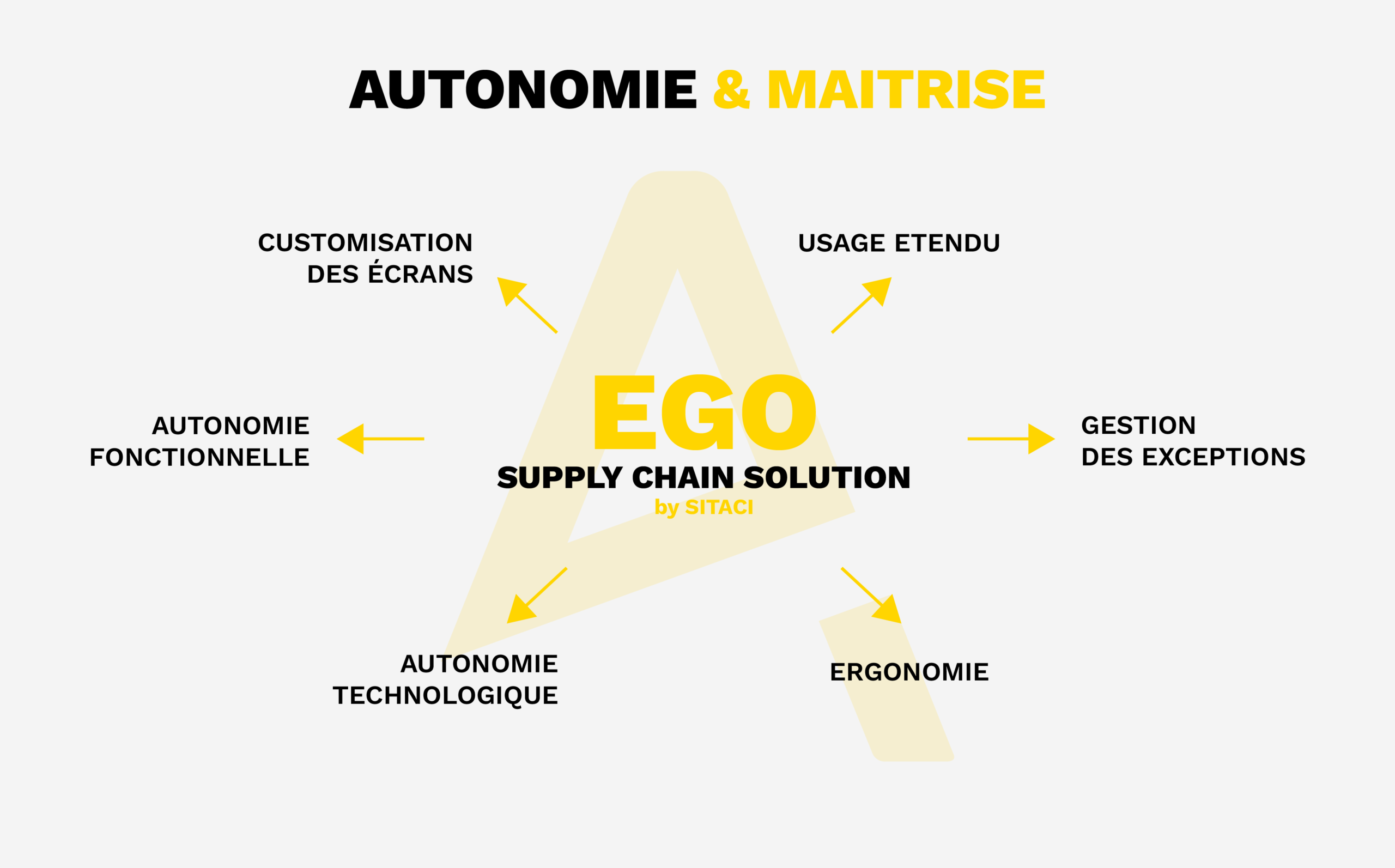

1- Master your processes independently

Our EGO WMS platform emphasizes flexibility and control over your logistics processes. You can easily build and adjust your business processes to meet your specific needs. With quick and easy configuration, you can scale your processes in line with your organization.

2- Gradual evolution with an adaptable and modular solution

The EGO WMS platform is designed to grow with your business. Thanks to its modular structure and function activation principle, it offers agile and responsive integration into your existing processes. You can develop your organization at your own pace, benefiting from proven modules integrated into the WMS platform.

3- Expand your scope of action beyond the warehouse

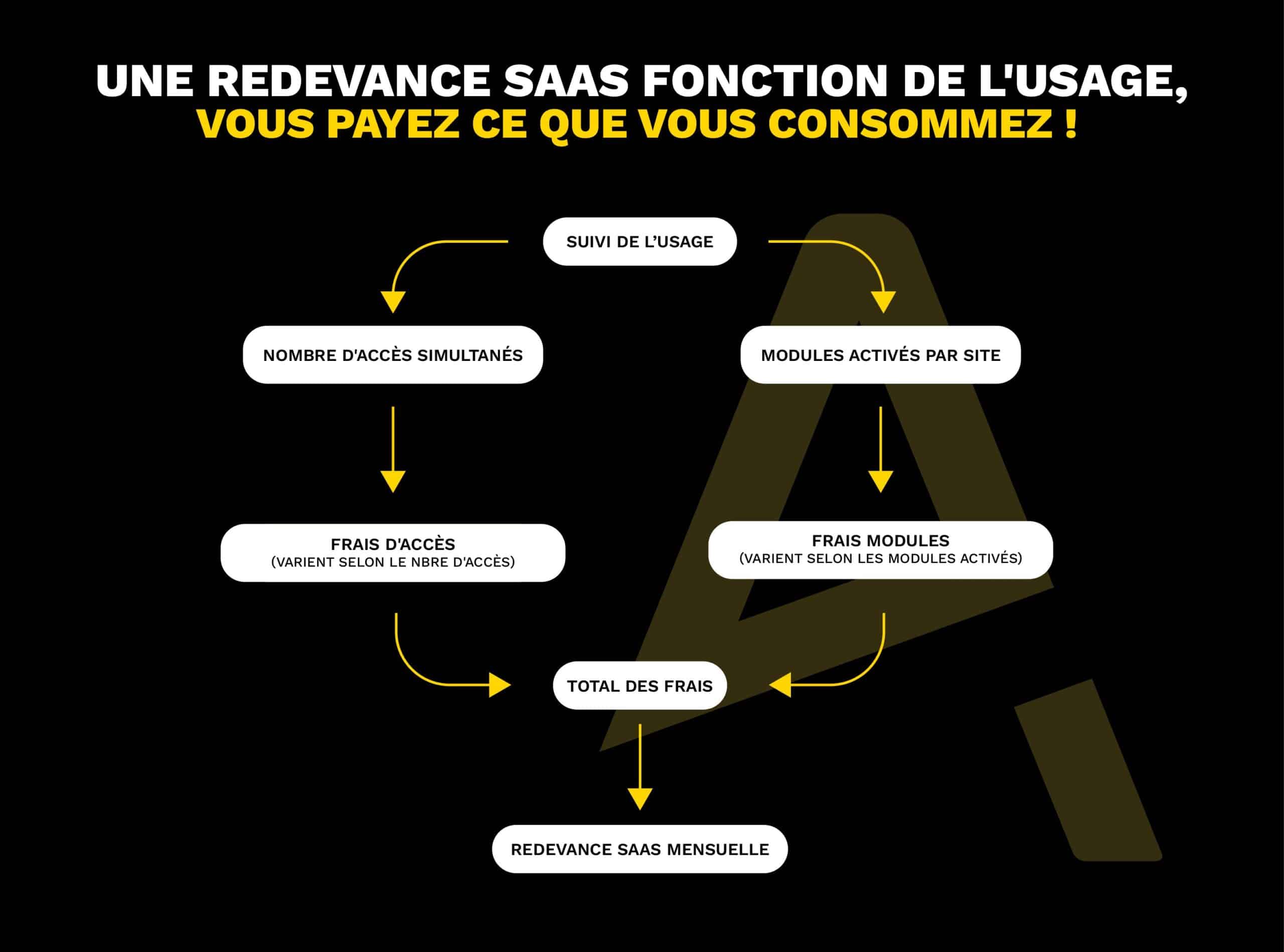

4- SaaS model: flexibility and savings

5- Rapid and efficient integration

Features covering all warehouse activities

Discover our features