NORMANDISE Pet Food

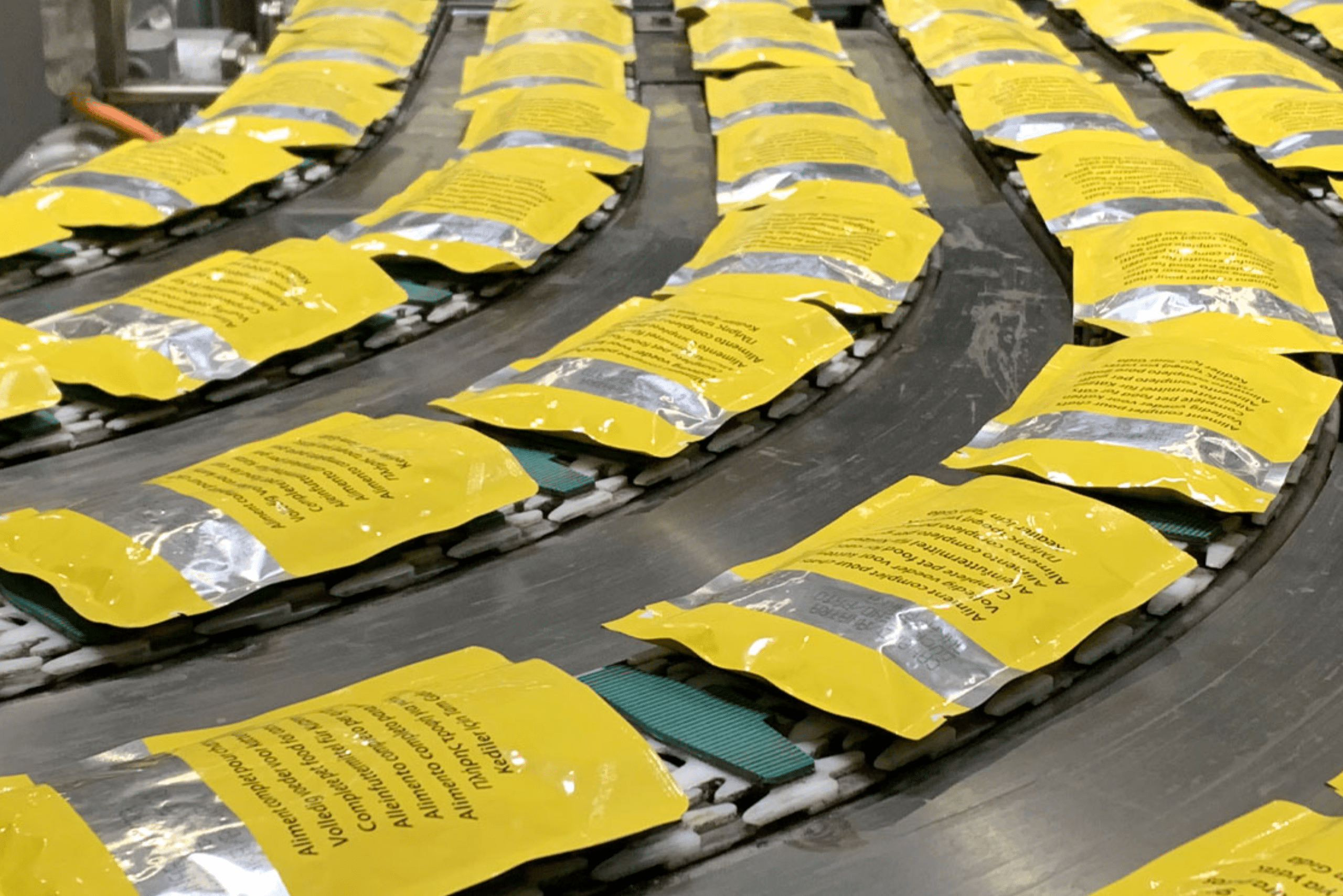

NORMANDISE Pet Food is a manufacturing and packaging factory specializing in the custom production of wet food products for dogs and cats. They have a wide range of recipes and textures to satisfy the desires, expectations and needs of their prospective customers, distributors, etc. Founded in 1991, the small Normandy company of 6 people has become, more than 30 years later, a cutting-edge mid-sized company with nearly 800 employees.

800

collaborators

180

million euros of turnover

3 500

pallets shipped/week

Complete digitalization of the manufacturing process

The project was quickly born, driven by the cessation of maintenance of the existing WMS.

Initially limited to the distribution of products, NORMANDISE Pet Food very quickly wanted to bring complete digitalization to its manufacturing process by equipping itself with a WMS solution for its industrial logistics.

This digitalization aimed to automate the supply of lines and allow the organization of buffer stocks in real time. The processes being complex and difficult to anticipate, NORMANDISE had to put in place a whole logic based on the real-time progress of its manufacturing orders in order to allow complete management:

- Shuttles,

- Lists to serve,

- From the power supply of the buffers.

This digitalization gave them the possibility of optimizing the Synthetic Yield Rate (SEE) on line and implementing a broader project to limit factory stock. This thus contributed to increasing production capacity by linking, almost natively, the factory with its distribution and storage platforms for raw materials and packaging items.

Our response

Bringing the scheduling to life

By integrating production orders (FO) and providing real-time information on their progress, the WMS EGO platform made it possible to bring scheduling to life. This resulted in the automatic generation of replenishment and shuttle orders to ensure hourly stock coverage for each production line.

These anticipated missions drawn from needs identified in real time have made possible the integration of LGV (laser-guided vehicles) supporting industrial logistics and simplifying management over a wide opening range: 3×8 7/7.

The main stages of the project

A deployment of the EGO WMS in 4 steps

The “La NORMANDISE” project was large-scale and closely linked to operations and production. It was designed to fit perfectly into the progressive digitalization of the factory.

Thus, the deployment of the WMS solution took place as follows:

- Deployment on the distribution platform

- Extension to the manufacturing/packaging area

- Expansion to the storage platform for raw materials and packaging items

- Latest deployment on the manufacturing of food product recipes.

Finally, flows have also been optimized by providing complete coupling with mechanized solutions:

- Bin turner,

- LGV,

- Palletizer.